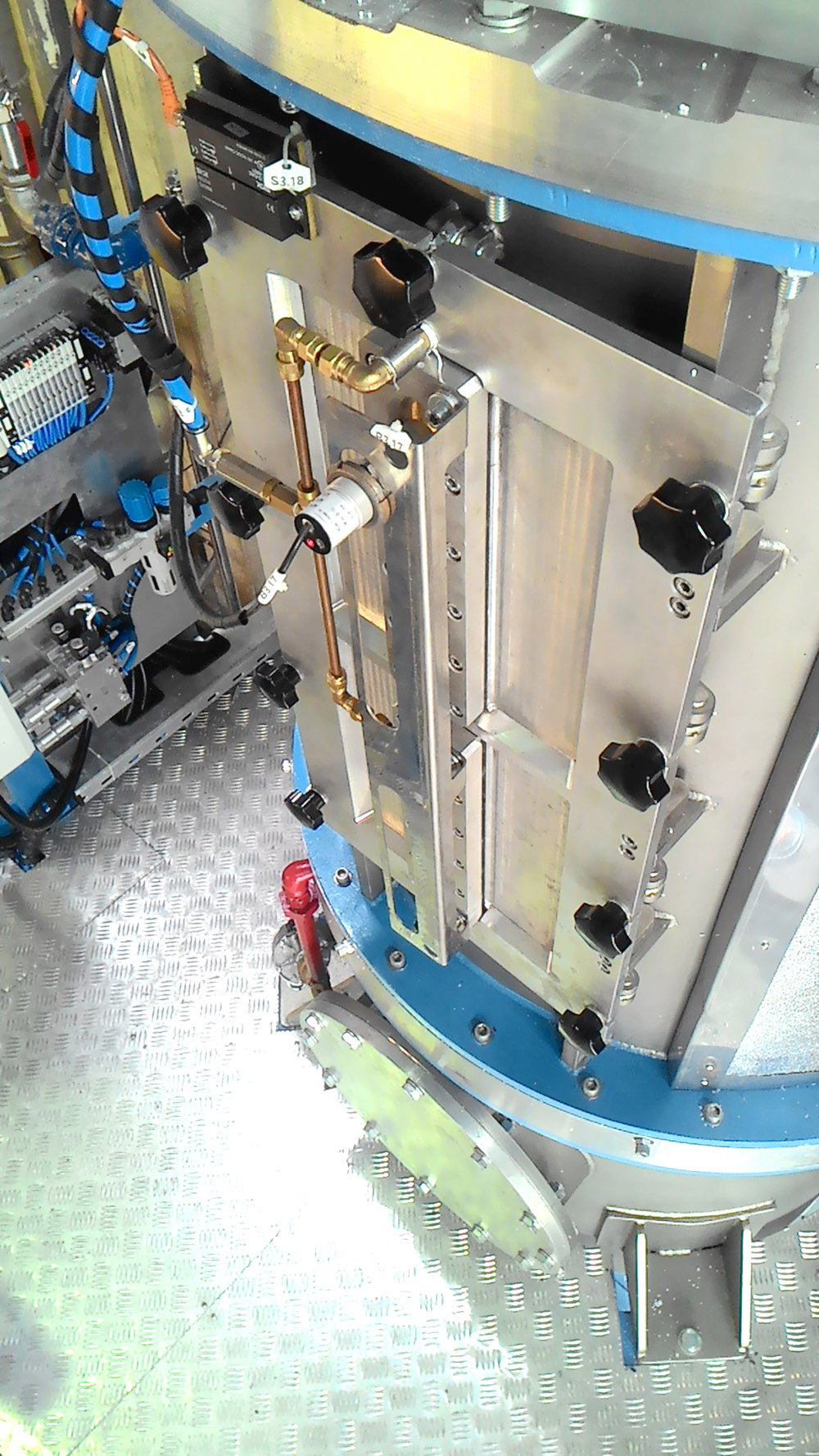

Expansion chamber made of AISI 304 stainless steel, cylindrical shape.

Agitator and accessories made of AISI 304 stainless steel, speed control via drive. With the adjustable speed in different steaming phases, enables processing of different materials.

Discharge door located on the floor of the vessel, to empty the chamber fast.

Fluidized bed dryer, inside floor parts made of AISI 304 stainless steel, where the expanded material going out from the expansion chamber to dry the beads. The unit is equipped with a steam-air heat exchanger inside, which avoid the beads from thermal shock.

Material Transport unit, has a rotary valve system, to send the material to the silos.

Machine has a built-in silo control system, with the rigth hardware you can operate this part. Pre-expanded beads from the pre-expander conveyed to the storage silos for 1st and 2 nd expansion stages

After the pre-expansion, you can select the silo from the display, where you want to send the eapanded material. The operator can select several silos at the same time with a priority.

The system follows the selection after the order finishes the machine stops as well. For 2nd expansion, same selection steps are possible. From all the silos, you can make 2nd expansion process.

This conveying system named silo top distribution and all the operation controlled via pre-expander panel.

High Density processing: The air and steam adjustment can be done automatically, in quantity and temperature during all expansion stages. This unit helps to expand densities over 30 kg/m³ till 50 kg/m³. To be on the safe side, densities over 30 kg/m³ should be expand at lower volumes . To do that the levels sensors must be adjusted correctly.

Material Loading Hopper

Volume 1.25 m3 which is approximately 1.100 kg EPS capacity. Equipped with flexible hexagonal feeder.

Alternatively material loading hopper; Capacity 3+1 (Octabin) 1100 kg

2nd Expansion Unit

This unit is necessary to proces under 12 kg/m³ bulk density. The pre-loading silo is located on the top of the expansion chamber, with electronic scale system to control the proper filling for second expansion. The PLC calculates the necessary amount (kg) of material for second expansion, and expand in a fixed volume. The filling from the silo to the machine is done by a vacuum fan.

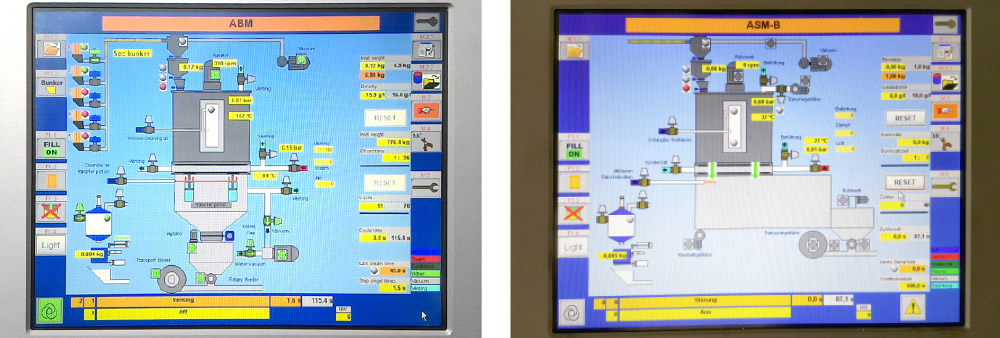

Machine Control Panel

Machine is controlled by SIEMENS S7 type PLC. Touch panel size 10.1” full color. With this display the operator can change process parameters, and recipes can be added, changed and saved in the PLC. Also can be transferred to any place.

Density Control Unit (Control-Adjust Density)

For checking the pre-expanded bulk density, via a sample material taken from the dryer. After each cycle, mateial taken from the dryer and weighed in fixed volume. The unit measures, and inspects the expansion values. Different measurements can be followed on the display. Production data can be saved or printed on a paper.

Material Transport Unit

Material Transport unit, has a rotary valve system, to send the material to the silos.

Fluidized Bed Dryer

Fluidized bed dryer, inside floor parts made of AISI 304 stainless steel, where the expanded material going out from the expansion chamber to dry the beads. The unit is equipped with a steam-air heat exchanger inside, which avoid the beads from thermal shock.

PRE-EXPANDER TYPE ASM-B Features and Advantages

- CE Certification,

- AISI 304 stainless steel, expansion chamber.

- Agitator, speed control via drive. (Allenbradley-USA)

- Fluidized bed dryer, inside floor parts made of AISI 304 stainless steel

- PLC Automation System (Siemens-Germany)

- Color Touch Screen Panel size 12” (Siemens Germany)

- Receipe Menu 99 pcs

- Pressure Sensor-Temperature Sensor (Jumo-Germany)

- Proportional Steam Control Valve (Gemu-Germany)

- Proportional Exhaust Control Valve (Gemu-Germany)

- SSWW bottom for fast cycle and less steam consumption (made in Belgium)

- Pneumatic Control Valves (Festo-Germany)

- Internet Service Module (Siemens-Germany) - optional

- Homogenous density distribution

- Automatic Density Control System with adjustment control - optional

- Steam Ventilation Hood

- The unit is equipped with a steam-air heat exchanger inside, dryer

- Material Transport unit, has a rotary valve system

|

Batch Pre-Expander Type |

ASM-B 900 |

ASM-B 2250 |

ASM-B 4500 |

ASM-BV 900 |

ASM-B 150 |

|

Capacity kg/h at 15g/l density |

480-500 kg/hour |

800-990 kg/hour |

1260-1500 kg/hour |

200-280 kg/hour |

187,5 kg/hour |

ASM-B 150 SMALL SCALE BATCH TYPE PRE-EXPANDER

- Working Pressure: max. 0,45 bar

- Chamber volume:150 lt

- Chamber material stainless steel - dryer stainless steel

- Dosaging - automatically with precision scales

- Scaling 1000/1(material feeding max 3,5 kg for 150 lt)

- Steaming and exhaust adjustment with proportional PVD valvesInstalled power : 8,4 kw

- Color : RAL 5012

- Capacity in kg/cycle: For 150 lt expansion level ;3.75 kg / per cycle and cycle time 70 sec.

- Means Hourly capacity 50 cycle x 3.75 kg =187,5 kg

- Consumption of steam (kg) per/cycle 1.8-2 kg steam per cycle Consumption of electricity kW per/cycle 8 Kw /hour -0.16 Kw /cycle

- Consumption of compressed air m³ per/cycle 100 -125 lt/cycle

- Density tolerance 1.5 -2%

ASM-BV 900 VACUM TYPE BATCH PRE-EXPANDER

- Chamber Diameter:900 mm

- Chamber Volume:0.6 m3

- Vacuum vessel:0,6 m3

- Vacuum pump: 7,5 kW

- Raw material with suction blower: 5,5 kW

- Raw material suction vessel stainless steel with ATEX sensor

- Raw material bunker

- Sensor ATEX type1 pc.level sensor ATEX type

- Production Capacity:

15 kg/m³ -(*)17/24 m³/ hour approx. 200-280 kg/hour

20 kg/m³ -(*)25/32 m³/ hour approx. 500-480 kg/hour

- (*)Mentioned values are avarage capacities, which is reachable with proper quality and the rigth type of the raw materials.For low density production, it is necessary to use the suitable raw material only. Air comsumption:±130 litre/min

- Max.air consumption on safety mode:±1.200 litre/min

SMALL SCALE BATCH TYPE PRE-EXPANDER ASM-B 150

Rawmaterial is sucked from container in rawmaterial via vacuum unit mounted on the machine. With scaling unit, materail is dosed to the dosing unit. Rawmaterial in the chamber is steamed as needed and is reached to the requested density.The expanded material is discharged to the bed-dryer by the openning door on the side of chamber.Dried material after expansion is transfered to the storage silos by the transfer pipes.Working Pressure: max. 0,45 bar

Chamber volume:150 lt

Chamber material stainless steel - dryer stainless steel

Dosaging - automatically with precision scales

Scaling 1000/1

(material feeding max 3,5 kg for 150 lt)

Steaming and exhaust adjustment with proportional PVD valves

Installed power : 8,4 kw

Color : RAL 5012

VACUUM BATCH PRE EXPANDER TYPE: ASM-BV 600

Vacuum chamber is located direct under the expansion vessel, accelerates the stabilization time. Drying is done by this unit instead of a fluid bed dryer. This type pre-expanders are used mainly by shape moulding plants. The accuracy of the expander, starts just after 5 cycles of starting of expansion process. Density is controlled by the PLC, adjusting the weight of raw material by each cycle automatically. Density Control Unit is used for checking the density each cycle and regulate the weight. Higher densities upto 100 g/lt is possible to expand with this pre-expander.Chamber Diameter:900 mm

Chamber Volume:0.6 m3

Vacuum vessel:0,6 m3

Vacuum pump: 7,5 kW

Raw material with suction blower: 5,5 kW

Raw material suction vessel stainless steel with ATEX sensor

Raw material bunker

Sensor ATEX type

1 pc.level sensor ATEX type

Production Capacity:

15 kg/m³ -(*)17/24 m³/ hour approx. 200-280 kg/hour

20 kg/m³ -(*)25/32 m³/ hour approx. 500-480 kg/hour

(*)Mentioned values are avarage capacities, which is reachable with proper quality and the rigth type of the raw materials.For low density production, it is necessary to use the suitable raw material only

.jpg)