Movement

Hydraulic system allows fast movemets with a soft action, or alternative Electrical drive even more faster action. All steam and air control is proportonally driven which creates energy saving and fast cycle times.

- Equipped with fast mould change system

- Proportional control for Steam & Air

- De-loading and Stacking robot

- Surface treatment mouldings

- Electrical drive with knee lever.

Machine Components

- Process Control Bachmann

- PLC Pneumatic Control Festo

- Hydraulic Drive Parker

- Electrical Component Schneider

- Process control Valves Gemü

- Electrical Servo Drive Schneider

- Gearbox Keb

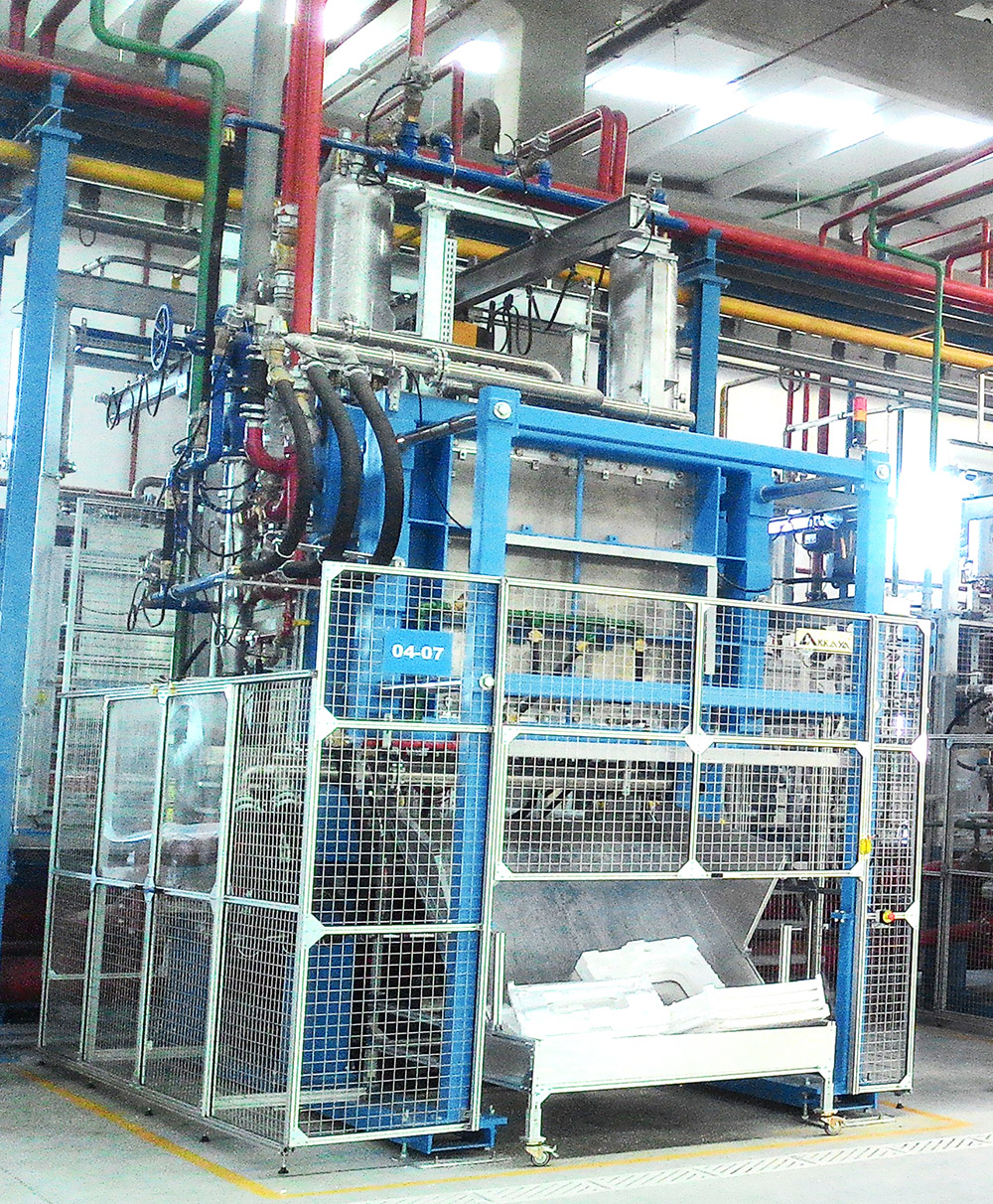

EPS MOULDING MACHINE TYPE: AEM-E

- CE Certification

- Operating pressure max. 1.6 bar standard

- Aluminium Profile Steam Chambers,

- Quick mould change system with clamping frame

- Back ejection plate, adjustable, on fixed side.

- Mould change rail incl. moveable manual hoist 1000/2000 kg.

- Pressured filling system 120 lt with 16 exits.

- Vacuum Unit with 1 vacuum pumps (POMVAK-Turkey)+ 1 water pump 4 kW (POMVAK-Turkey)

- Air Blower 2,2 kW for material suction to pressure filler.

- Control Panel/Process Control (BACHMANN-AUSTRIA)/Display 12” color touch panel (ASEM-ITALY)

- Electronic Stroke Measuring Device (TR-Germany)

- Prop.Regulation (Germany)

- Pneumatic Command and Control (Festo-Germany)

- High Speed Hydraulic Unit 7,5 kW (PARKER-Germany)

EPS MOULDING MACHINE TYPE: AEM-K

- CE Certification,

- Operating pressure max. 1.6 bar Standard

- Moulding Area: 2075*1475 mm:3,060 m2

- Female Flange Dim.: 2150*1550 mm

- Male Flange Dim.: 2125*1525 mm

- Suitable mould connection design for monoblock steam chamber and fast mould change system

- Hydraulic Stroke: 1500 mm

- Back ejection plate, adjustable, on fixed side.

- Mould change rail incl. moveable manual hoist 2000 kg.

- Pressured filling system 300 lt with 32 exits.

- Vacuum Unit with 2 vacuum pumps (POMVAK-Turkey)+ 1 water pump 4 kW (POMVAK-Turkey)

- Air Blower 2,2 KW for material suction to pressure filler.

- Control Panel/Process Control:(BACHMANN-AUSTRIA)/Display 12” color touch panel (ASEM-ITALY)

- Electronic Stroke Measuring Device (TR-Germany)

- Prop. Regulation (Germany)

- Pneumatic Command and Control (Festo-Germany)

- High Speed Hydraulic Unit 11 kW (PARKER-Germany)

EPS ELECTRICAL DRIVE

MOULDING MACHINE TYPE: AEM-EE

- CE Certification,

- Electric Servo Drive (KEB-Germany)

- Operating pressure max. 1.6 bar standard

- Aluminium Profile Steam Chambers,

- Quick mould change system with clamping frame

- Back ejection plate, adjustable, on fixed side.

- Mould change rail incl. moveable manual hoist 1000 kg.

- Pressured filling system 120 lt with 16 exits.

- Vacuum Unit with 1 vacuum pumps (POMVAK-Turkey)+ 1 water pump 4 kW (POMVAK-Turkey)

- Air Blower 2,2 kW for material suction to pressure filler.

- Control Panel/Process Control: (BACHMANN-AUSTRIA)/Display 12” color touch panel (ASEM-ITALY)

- Prop. Regulation (Germany)

- Pneumatic Command and Control (Festo-Germany)

EPP MOULDING MACHINE TYPE: AEM-E-PP

- CE Certification

- Operating pressure max. 5 bar standard

- Steel steam chamber system, aluminium coated

- with outside thermal insulation.

- Multi position clamping/loading of male/female through combined

- hydraulic/mechanic locking system.

- Quick mould-change system with clamp-frame

- Back ejection plate, adjustable, on fixed side.

- Mould change rail incl. moveable manual hoist 1000/2000 kg.

- Pressure filling system 150 lt with 16 exits.

- Vacuum Unit with 1 vacuum pumps (POMVAK-Turkey)+ 1 water pump 4 kW (POMVAK-Turkey)

- Air Blower 2,2 kW for material suction to pressure filler.

- Control Panel/Process Control: (BACHMANN-AUSTRIA)

- Display 12” color touch panel (ASEM-ITALY)

- Electronic Stroke Measuring Device (TR-Germany)

- Prop.Regulation (Germany)

- Pneumatic Command and Control (Festo-Germany)

- High Speed Hydraulic Unit 7,5 kW (PARKER-Germany)

EPS-EPP FILLING INJECTORS

- Our injector is produced to work with 2air or 3 air connection. (Means it can be used on all the machines)

- It is longer than others.~ 400 mm

- It is quick lock design.Easy service and maintanance

- Can be used for fast mould change systems.You need only the outershell.You do not need to purchase complete injector.

- Inside design is made of aluminium profile.There is a channel inside which material flow through.It canbe used for any density.

- It is coming without clamping ring.

- Better price comparing to the similiar

EPP MOULDING MACHINE AEM-TU 160/120

- CE Certification

- Operating pressure max. 5 bar standard

- Steam chamber system,Table press, meaning of possibility of connecting standart steam chambers and monoblock steam chambers.

- Multi position clamping/loading of male/female through combined

- hydraulic/mechanic locking system.

- Quick mould-change system with clamp-frame

- Back ejection plate, adjustable, on fixed side.

- Mould change rail incl. moveable manual hoist 1000/2000 kg

- Pressure filling system 150 lt with 20 exits.

- Vacuum Unit with 1 vacuum pumps (POMVAK-Turkey)+ 1 water pump 4 kW (POMVAK-Turkey)

- Air Blower 2,2 KW for material suction to pressure filler.

- Control Panel/Process Control:(BACHMANN-AUSTRIA)/Display 12” color touch panel (ASEM-ITALY)

- Electronic Stroke Measuring Device (TR-Germany)

- Prop.Regulation (Germany)

- Pneumatic Command and Control (Festo-Germany)

- High Speed Hydraulic Unit 7,5 kW (PARKER-Germany)

EPP MOULDING MACHINE TYPE: AEM-K PP

- CE Certification,

- Operating pressure max. 5 bar standard

- Steel steam chamber system, aluminium coated

- with outside thermal insulation.

- Multi position clamping/loading of male/female through combined

- hydraulic/mechanic locking system.

- Quick mould-change system with clamp-frame

- Back ejection plate, adjustable, on fixed side.

- Mould change rail incl. moveable manual hoist 1000 kg.

- Pressure filling system 90 lt with 18 exits.

- Vacuum Unit with 1 vacuum pumps (POMVAK-Turkey)+ 1 water pump 4 kW (POMVAK-Turkey)

- Air Blower 2,2 KW for material suction to pressure filler.

- Control Panel/Process Control:(BACHMANN-AUSTRIA)/Display 12” color touch panel (ASEM-ITALY)

- Electronic Stroke Measuring Device (TR-Germany)

- Prop.Regulation (Germany)

- Pneumatic Command and Control (Festo-Germany)

- High Speed Hydraulic Unit 7,5 kW (PARKER-Germany)