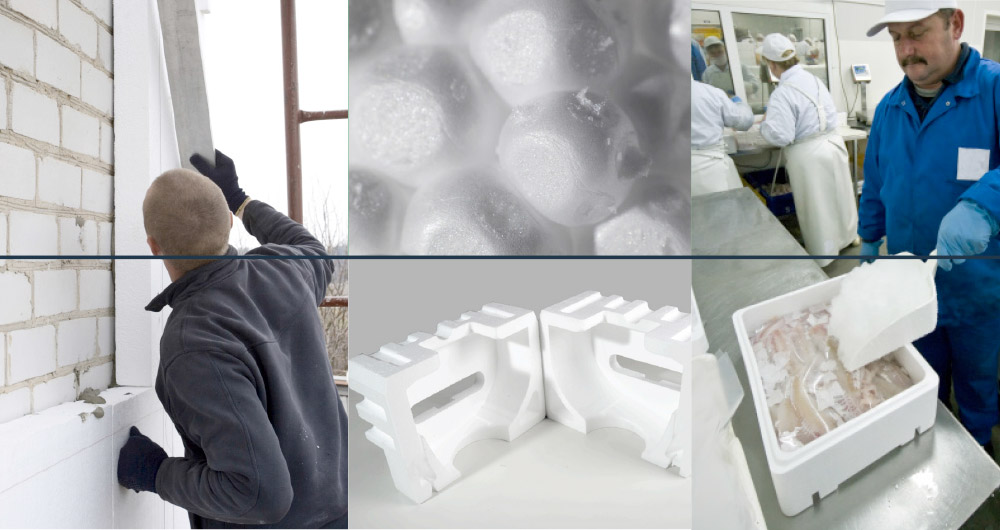

- Packing Inserts

- Box-type Packs

- Composite Mouldings

- Roof Construction

- (Flot and pitched Roofs)

- Wall construction

- Insulating Plasters

- Lightweight concrete

- Prefabricated systems

- Floor construction for sound

- and heat insulation

- Dreinage boards

- Foundation Engineering

STURDY

Polystyrene protects against moisture and maintains its strength and shape even after long periods of time. Containers and lids close tightly, guarding against leaks while maintaining an ideal temperature. Additionally, polystyrene food and meat trays perform extremely well in automated processing equipment.

Polystyrene packaging offers exceptional protection. Its shape can be molded (custom fit) to parts and products, maximizing its excellent cushioning characteristics.

EFFICIENT

Only about five percent of a foam package is polystyrene, the rest is air! Polystyrene provides the superior insulating quality that helps hold food at the optimal eating or drinking temperature longer than many alternatives. This helps to guard against waste. Polystyrene maintains hot food at temperatures required by many health departments, yet remains comfortable to hold.

SANITARY

Tests have shown that disposable food service ware (such as polystyrene cups, plates and utensils) is more sanitary than reusable service ware. Health officials, who regulate food service operations in schools, hospitals and restaurants, recognize this important product benefit. In fact, national environmental health officials passed a resolution stating that restricting the use of disposable cups, plates and containers would have a potentially adverse impact on disease prevention.

ECONOMICAL

Polystyrene food service products are generally more economical to use than disposable paperboard products and reusable food service items. The wholesale price of polystyrene disposable food service products is often approximately two to three times less than an equivalent disposable paper container, and four to five times less than a comparable reusable food service item when the costs of equipment, labor, water, electricity, and detergent costs are included.

CONVENIENT

Today’s busy lifestyles require the convenience of affordable and quick take-out meals. Polystyrene packaging meets the demands of today’s modern lifestyles by offering an economical and high quality food service product.

EPS-EPP Pre-Crusher & Grinder

- High capacity.

- Isolated body for low noise operation.

- Easy accessible machine equipment.

- Changable sieve to 6 mm bead size.

- Minimum dust content in regranulated material.

- Can be used with de-dusting unit (ATM 1500)

De-Dusting Unit

- One step dust seperation chamber.

- Changeable sieve and brush.

- Large area of dust seperation chamber.

- Minumum dust content in the recycled material.

Compactor For Dust

Density from 175-250 kg/m3 depending on materialStandard silo bag dimensions: 2x2x7 m (can be made custom according to customer needs)

Min. and Max. Level Sensors on the silo bag

Vibration unit on the cone

Hopper Opening: 400*780 mm

Capacity: 35-45 kg/h

Size of Octagonal Rod(compacted material): 150*150 mm

Dusts are collected in silo and compacted by the compactor under the silo.

EPS Scrap & Dust Melting Unit

Capacity: 30-50 kg/hrFeeding inlet: 400*780 mm

Silo volume: 17 m3

Dusts are gathered in the silo and they are melted via extruder under the silo.

Silo included (Bag-Frame only).

Basic Body

During cutting insulating boards from blocks reusable cutting waste is generated which in general becomes recycled. Via the mixing and dosing unit recycled and virgin material is mixed and re-converted to blocks.

A double rotary star valve unit with combined outlet is located below a 10 m³ storage-silo for recycled and a 10 m³ storage-silo for virgin material. The percentage of regrind to the virgin material is step-less adjustable from 5 % to 50% by different rotation speed of the rotary star valves. Electronic speed control of the driving motors guarantees a constant mixing-ratio. By switching off the dosing unit for regrind only virgin material is supplied to the block-mould.

The filling levels of the storage silos get monitored and controlled by level sensors.

Technical Data

- Flexible silo bag and silo frame. Anti-static silo bag.

- Anti-corrosion silo frames.

- Preperation for automatic storage system.

- Galvanised transport pipes.

- Custom made silos

- PLC controlled silo automation.

Login

Representatives

- Foamatec Gmbh / Central Europa

- Burry Trading / France and N.Africa

- EPS Production Tech. / Balkan's

- Europlast Handelsgesellschaft M.B.H.A / Austuria

- Libero Piscitelli / Italy and S.America

- Eugen Krebs / Ukraine

For contact detail click here

Contact

About Us

Since 1980 AKKAYA engineers and manufactures machinery for processing expandable Polystyrene (EPS) Intensive exchange of experience with all our customers enabled the engineering of cost-efficient, highly productive, easy to maintain and user friendly machines and production lines...